Raw Material Handling

At Active Steel Forge, we recognize that the foundation of…

At Active Steel Forge, we recognize that the foundation of…

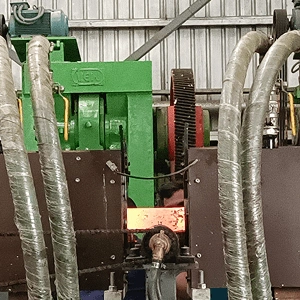

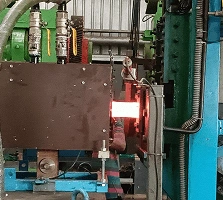

At Active Steel Forge, we offer advanced heating facilities designed…

Experience unmatched cutting precision and efficiency with our advanced cutting…

At Active Steel Forge, our advanced forging facilities offer unmatched…

At Active Steel Forge, we specialize in providing advanced heat…

Experience unmatched precision and superior quality with our advanced CNC…

At Active Steel Forge, we offer advanced heating facilities designed to deliver consistent, high-quality results. Whether for pre-heating, post-heating, or heat treatment processes, our state-of-the-art heating technologies ensure precision and performance in every component.

From maintaining exact temperature control to enhancing the material properties, our heating services ensure that each part meets the highest industry standards for strength, durability, and precision.

Explore how we leverage advanced heating techniques for optimal results.

Our heating equipment offers precise temperature control, ensuring uniform heating across all materials for superior results.

Heating processes improve the material’s hardness, strength, and flexibility, leading to better performance and longevity.

With cutting-edge heating systems, we ensure quick, efficient processes without compromising quality or performance.

Comprehensive solutions for all your heating and material enhancement needs.

At Active Steel Forge, we utilize a range of advanced heating methods to meet the requirements of even the most demanding projects.

Highly controlled heating for precise results, ideal for hardening and surface treatments.

Uniform heat treatment for a variety of metals to improve mechanical properties like toughness and hardness.

Efficient and cost-effective heating for large volume operations, offering uniform temperature distribution.

Quick, precise heating for fast turnaround times, especially for thin materials or rapid production cycles.

Experience our state-of-the-art facility from anywhere

Founder/CMD

Team Size

Annual Capacity

Established

1

We begin by discussing your material and heating requirements to determine the best approach.

2

Customizing the heating process to optimize material properties, from ramp rates to heating times.

3

Preparing and calibrating our heating equipment to ensure accurate and consistent performance.

4

Every batch is monitored and tested to ensure the correct heat treatment specifications are met.

Stay ahead with our advanced heating equipment and technology.

At Active Steel Forge, we continually upgrade our heating technologies to ensure maximum precision, efficiency, and repeatability. Our facilities feature state-of-the-art heating systems that allow us to handle even the most complex heating requirements.

Custom heating solutions tailored to your project’s needs.

At Active Steel Forge, we understand that every client has specific needs and goals. That’s why we tailor our heating processes to meet your exact specifications, ensuring that every part performs optimally.

Performance

Take a look at our impact and capabilities in heating services.

Consistency

Parts Heat Treated

Client Satisfaction

Heat Treatment Capacity

Their in-house capabilities and customization options have allowed us to streamline our production process. Highly recommended!

Maruti Suzuki

"The precision and durability of the components we receive from Active Steel Forge are unmatched. We trust them for all our forging requirements."

Ford Motor Company

Active Steel Forge has been a reliable partner for our manufacturing needs. Their commitment to quality and timely delivery has made a significant difference in our operations.

Hero MotoCorp Ltd:

Get in touch with our experts today