Raw Material Handling

At Active Steel Forge, we recognize that the foundation of…

At Active Steel Forge, we recognize that the foundation of…

At Active Steel Forge, we offer advanced heating facilities designed…

Experience unmatched cutting precision and efficiency with our advanced cutting…

At Active Steel Forge, our advanced forging facilities offer unmatched…

At Active Steel Forge, we specialize in providing advanced heat…

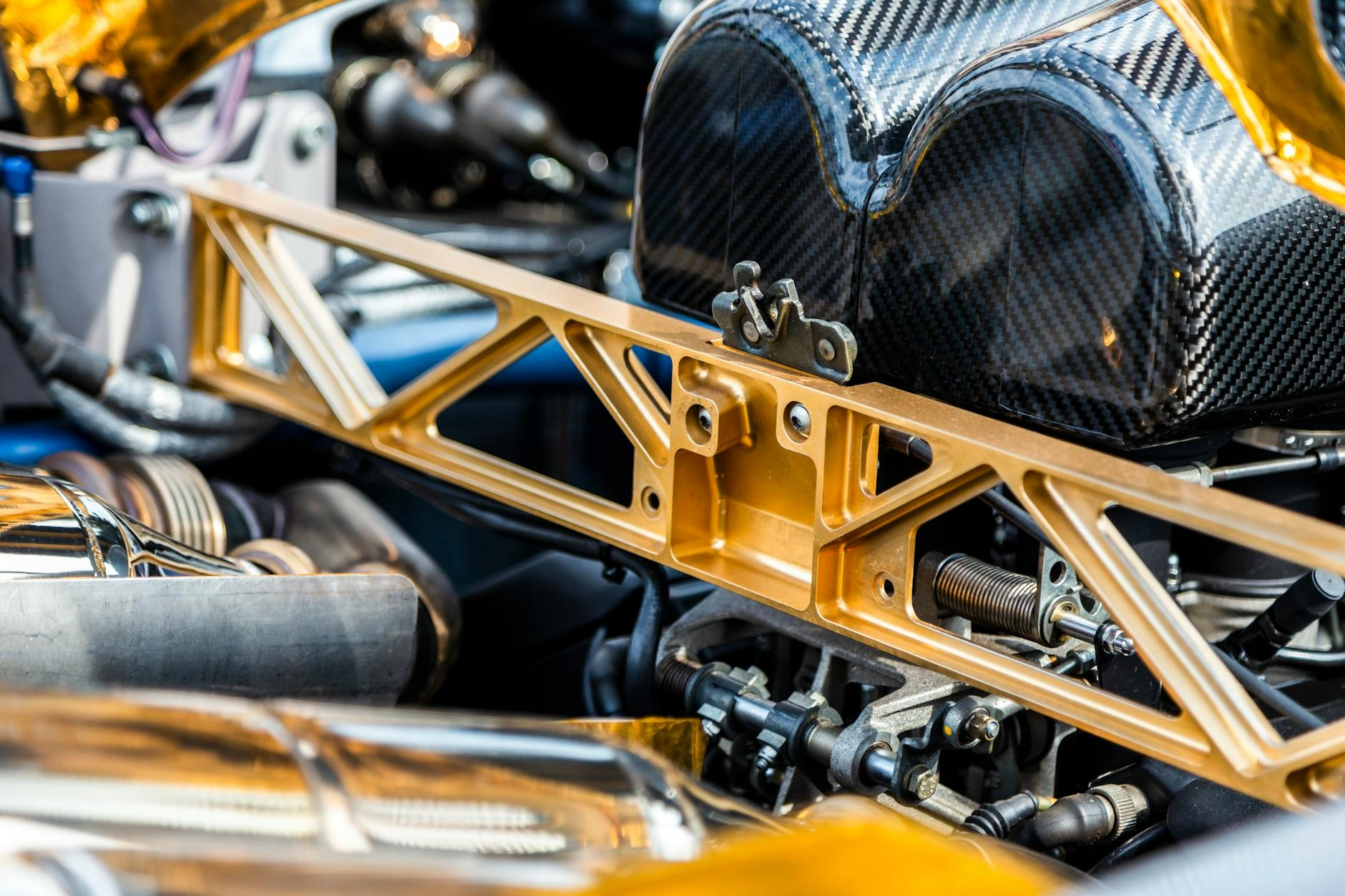

Experience unmatched precision and superior quality with our advanced CNC…

5 min Read

Forging has been an essential part of industrial manufacturing for centuries, evolving from traditional blacksmithing techniques to state-of-the-art CNC finishing solutions. Today, industries demand precision, efficiency, and durability, all of which are achieved through advanced forging methods. This article explores the transformation of forging, the role of CNC finishing, and how Active Steel Forge is pioneering these techniques to deliver superior products.

Forging is one of the oldest metalworking processes, dating back thousands of years. Initially, metals were manually hammered into shape using primitive tools. Over time, technological advancements introduced powered hammers, hydraulic presses, and automated forging machines that revolutionized the industry.

In the modern era, forging has become highly specialized. The demand for precision components in industries such as automotive, aerospace, and heavy machinery has driven innovation in forging techniques. Companies like Active Steel Forge have embraced these advancements, ensuring high-quality forged components tailored to industry needs.

While forging shapes the metal, CNC finishing is essential for achieving the final precision required for industrial applications. CNC (Computer Numerical Control) machining utilizes automated tools to refine forged components, ensuring exact tolerances and superior surface finishes.

CNC finishing provides:

Founded in 2012, Active Steel Forge has become a leader in forging and CNC finishing, offering a complete in-house manufacturing process. The company processes over 425 tons of steel per month, specializing in high-quality bearing rings and custom auto components.

With a team of 120+ professionals and an annual capacity of 3000 MT, the company has positioned itself as a trusted partner for industries requiring precision engineering.

The evolution of forging and CNC finishing has transformed modern manufacturing. Companies like Active Steel Forge leverage advanced technologies to ensure high-quality production. By combining traditional craftsmanship with cutting-edge machinery, they continue to meet the growing demands of global industries.

Get in touch with our experts today