Raw Material Handling

At Active Steel Forge, we recognize that the foundation of…

At Active Steel Forge, we recognize that the foundation of…

At Active Steel Forge, we offer advanced heating facilities designed…

Experience unmatched cutting precision and efficiency with our advanced cutting…

At Active Steel Forge, our advanced forging facilities offer unmatched…

At Active Steel Forge, we specialize in providing advanced heat…

Experience unmatched precision and superior quality with our advanced CNC…

13 min Read

Ring rolling is a specialized forging process that produces seamless rings with exceptional strength, dimensional accuracy, and versatility. This technique has become indispensable in various industries, from aerospace and automotive to heavy machinery and energy. This comprehensive guide delves into the intricacies of ring rolling, exploring its benefits, applications, and the science behind its effectiveness.

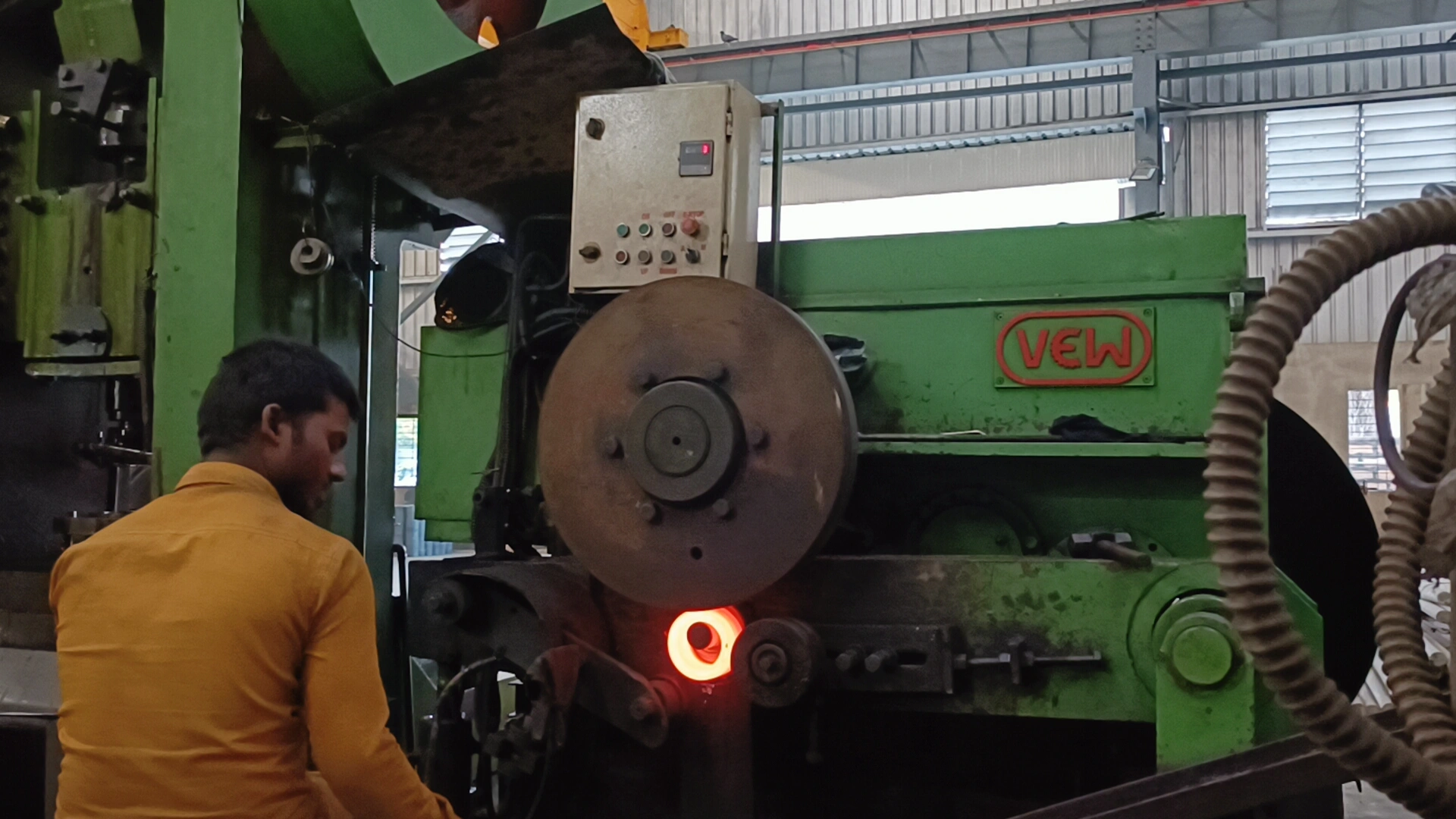

The ring rolling process begins with a pre-formed, heated metal ring blank, often created through upsetting or piercing. This blank is placed onto a mandrel, which determines the inner diameter of the final ring. The mandrel rotates while a rolling mill, equipped with a driven roll, applies pressure to the outer diameter of the ring. As the ring rotates and the roll applies pressure, the ring’s diameter expands, and its cross-sectional area is reduced. This process continues until the desired dimensions are achieved.

Several variations of ring rolling exist, including:

Ring rolling offers a multitude of advantages over other manufacturing processes, making it a preferred choice for high-quality ring production:

Ring-rolled products find applications in a wide range of industries:

The effectiveness of ring rolling stems from the principles of metal forming and material science. The process involves plastic deformation of the metal, which alters its microstructure and mechanical properties.

Compared to other manufacturing methods, such as casting, forging, and machining, ring rolling offers several distinct advantages:

The ring rolling industry is continuously evolving, with ongoing research and development focused on improving the process and expanding its capabilities:

Ring rolling is a powerful and versatile forging process that offers numerous benefits for producing high-quality, seamless rings. Its ability to enhance strength, improve material utilization, ensure dimensional accuracy, and cater to diverse design requirements makes it an indispensable technology in various industries. As technology continues to advance, ring rolling is poised to play an even greater role in shaping the future of manufacturing. The ongoing developments in automation, materials science, and process control will further enhance its capabilities and expand its applications. For manufacturers seeking high-performance, reliable, and cost-effective ring solutions, ring rolling remains a leading choice.

Get in touch with our experts today