Raw Material Handling

At Active Steel Forge, we recognize that the foundation of…

At Active Steel Forge, we recognize that the foundation of…

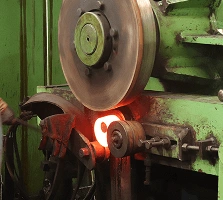

At Active Steel Forge, we offer advanced heating facilities designed…

Experience unmatched cutting precision and efficiency with our advanced cutting…

At Active Steel Forge, our advanced forging facilities offer unmatched…

At Active Steel Forge, we specialize in providing advanced heat…

Experience unmatched precision and superior quality with our advanced CNC…

At Active Steel Forge, our advanced forging facilities offer unmatched strength, precision, and reliability for all your component needs. Whether it’s for high-performance automotive parts, industrial components, or custom designs, we provide expert forging services that ensure every part is manufactured with optimal strength and durability.

Our forging capabilities allow us to deliver components that meet the highest standards for quality, consistency, and performance in the most demanding environments.

Explore the advantages of our advanced forging techniques.

Forging provides superior mechanical properties, ensuring that the final components are stronger, more durable, and able to withstand extreme conditions.

With our advanced forging technology, we achieve tight tolerances and precise dimensions, ensuring that every component is manufactured to your exact specifications.

Our forging processes are optimized for speed and efficiency, allowing us to produce high-quality components with fast turnaround times.

Comprehensive solutions for all your forging needs.

At Active Steel Forge, we offer a range of specialized forging services to meet the diverse requirements of industries like automotive, aerospace, and industrial machinery.

Precision-forged parts with high strength and close tolerances, ideal for complex shapes and intricate details.

Ideal for large, simple parts, open die forging ensures high-quality results for custom and heavy-duty components.

Specialized forging for ring-shaped components, perfect for use in turbines, valves, and other high-stress applications.

A method used for forging materials at consistent temperatures, ideal for complex and high-performance alloys.

Experience our state-of-the-art facility from anywhere

Founder/CMD

Team Size

Annual Capacity

Established

1

We begin by understanding your requirements to deliver precisely tailored parts.

2

Optimizing design and tooling for peak forging efficiency.

3

Configuring forging presses for maximum strength and precision.

4

Each component undergoes strict quality checks for durability and performance.

Leveraging cutting-edge technology for superior results.

At Active Steel Forge, we continually invest in the latest forging technologies to deliver outstanding results, whether it’s for large-scale production or highly specialized components.

Tailored forging solutions designed to meet your needs.

At Active Steel Forge, we prioritize your unique needs. We work closely with each client to ensure the forging process meets their specific goals, ensuring the final components align with both their design and performance requirements.

Performance

Discover the results of our advanced forging capabilities.

Strength Consistency

Parts Forged

Client Satisfaction

Production Capacity

Their in-house capabilities and customization options have allowed us to streamline our production process. Highly recommended!

Maruti Suzuki

"The precision and durability of the components we receive from Active Steel Forge are unmatched. We trust them for all our forging requirements."

Ford Motor Company

Active Steel Forge has been a reliable partner for our manufacturing needs. Their commitment to quality and timely delivery has made a significant difference in our operations.

Hero MotoCorp Ltd:

Get in touch with our experts today