Raw Material Handling

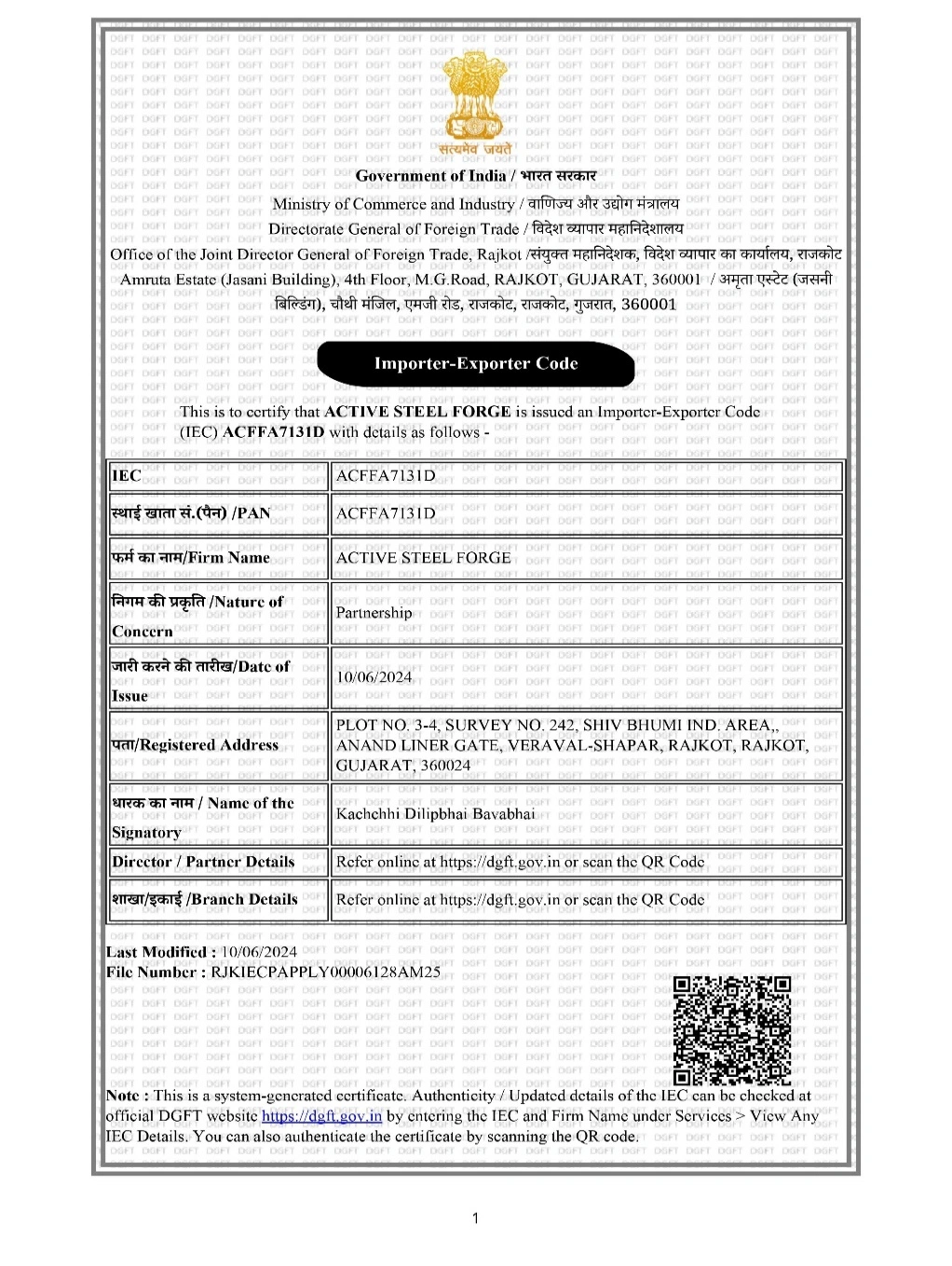

At Active Steel Forge, we recognize that the foundation of…

At Active Steel Forge, we recognize that the foundation of…

At Active Steel Forge, we offer advanced heating facilities designed…

Experience unmatched cutting precision and efficiency with our advanced cutting…

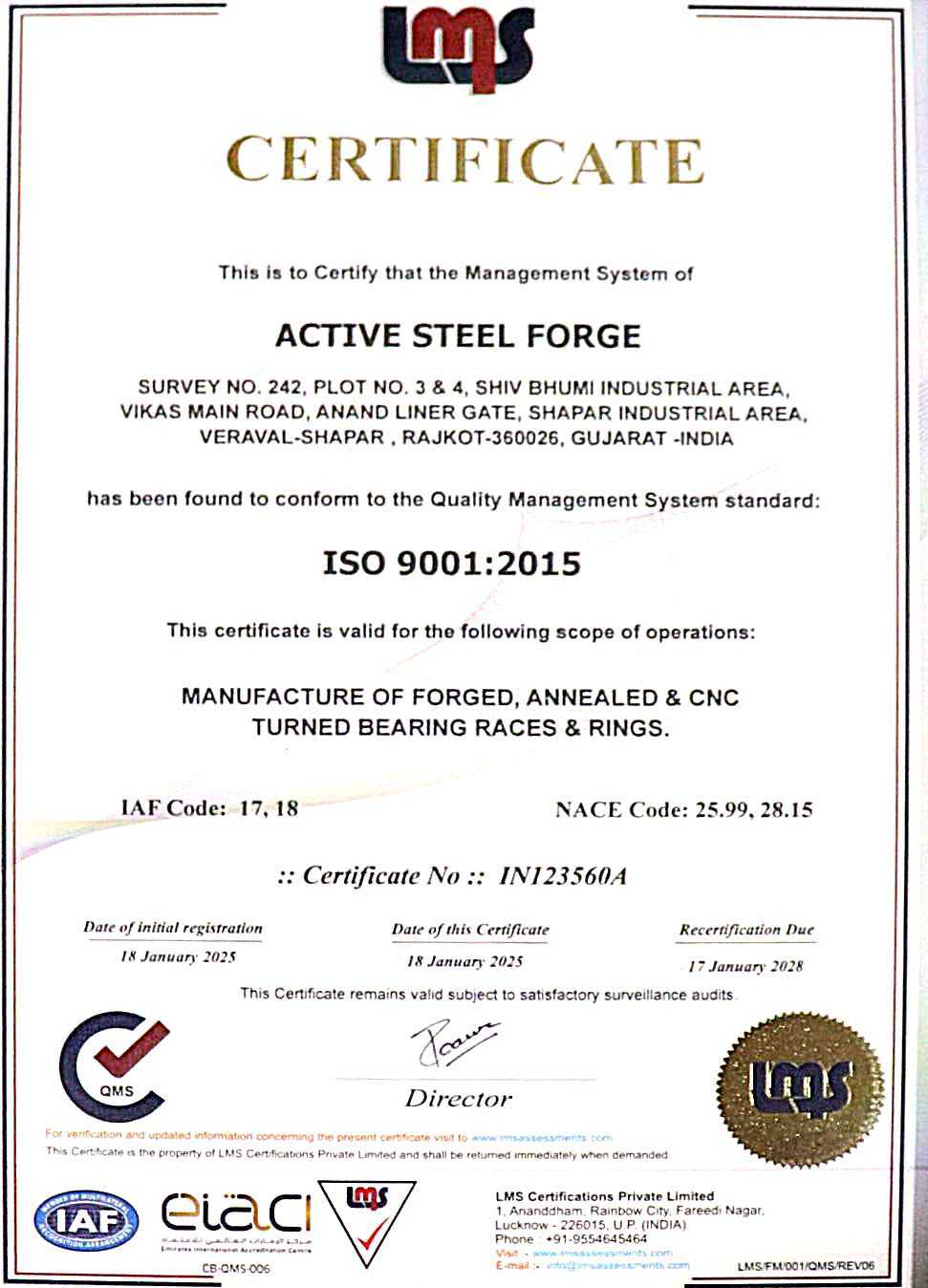

At Active Steel Forge, our advanced forging facilities offer unmatched…

At Active Steel Forge, we specialize in providing advanced heat…

Experience unmatched precision and superior quality with our advanced CNC…

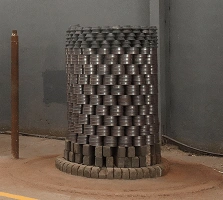

At Active Steel Forge, we specialize in providing advanced heat treatment services that enhance the mechanical properties, durability, and performance of your components. Whether you need to improve hardness, wear resistance, or strength, our heat treatment processes deliver exceptional results for all types of materials.

Our state-of-the-art heat treatment facilities allow us to precisely control temperature, time, and cooling rates, ensuring your components meet the highest standards of performance in a wide range of industries.

Unlock the benefits of heat-treated parts for superior performance.

Heat treatment increases the hardness of metals, providing resistance to wear, corrosion, and fatigue, which is critical for parts exposed to high-stress environments.

By controlling the cooling rate, heat treatment can significantly increase the tensile and yield strength of materials, making components stronger and more reliable.

With a variety of heat treatment processes at our disposal, we can tailor the properties of your components to meet specific performance requirements, from low to high temperature ranges.

Comprehensive solutions for all your heat treatment needs.

At Active Steel Forge, we offer a range of heat treatment services that can be customized to meet the specific needs of your components.

A process that involves heating and then slowly cooling metal to remove internal stresses, increase ductility, and improve machinability.

Rapidly cooling hot metal in water, oil, or air to harden it, making it ideal for components requiring high strength and wear resistance.

Reheating quenched parts to a lower temperature to relieve internal stresses and achieve the desired balance between hardness and toughness.

Adding carbon to the surface layer of steel to improve wear resistance while maintaining a tough core.

Experience our state-of-the-art facility from anywhere

Founder/CMD

Team Size

Annual Capacity

Established

1

We assess material and performance needs to select the ideal heat treatment process.

2

We tailor heat treatment to achieve your desired material properties.

3

We customize heat treatment for optimal material properties.

4

Each component undergoes inspection and hardness testing to meet standards.

Precision and control for optimal material performance.

At Active Steel Forge, we continually invest in advanced heat treatment technologies to provide the best results for our clients.

Customized solutions to meet your exact needs.

At Active Steel Forge, we understand that each project has its unique challenges, and we provide heat treatment solutions tailored to your specific requirements.

Performance

Watch how we transform raw steel into precision-engineered components

Hardness Consistency

Components Heat Treated

Client Satisfaction

Heat Treatment Capacity

Their in-house capabilities and customization options have allowed us to streamline our production process. Highly recommended!

Maruti Suzuki

"The precision and durability of the components we receive from Active Steel Forge are unmatched. We trust them for all our forging requirements."

Ford Motor Company

Active Steel Forge has been a reliable partner for our manufacturing needs. Their commitment to quality and timely delivery has made a significant difference in our operations.

Hero MotoCorp Ltd:

Get in touch with our experts today