Raw Material Handling

At Active Steel Forge, we recognize that the foundation of…

At Active Steel Forge, we recognize that the foundation of…

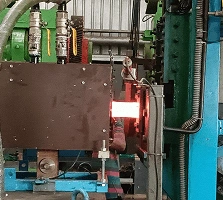

At Active Steel Forge, we offer advanced heating facilities designed…

Experience unmatched cutting precision and efficiency with our advanced cutting…

At Active Steel Forge, our advanced forging facilities offer unmatched…

At Active Steel Forge, we specialize in providing advanced heat…

Experience unmatched precision and superior quality with our advanced CNC…

Experience unmatched cutting precision and efficiency with our advanced cutting facilities. At Active Steel Forge, we utilize cutting-edge technology to provide high-quality cutting services, whether for prototypes, production runs, or custom specifications.

Our state-of-the-art cutting facilities ensure every component meets strict dimensional and quality standards, delivering superior accuracy, consistency, and performance.

See how we transform raw materials into high-quality components.

Our cutting technology ensures precise cuts that meet your exact specifications, even down to the micron level.

With our advanced machinery, we can complete large orders quickly while maintaining exceptional quality.

We can handle a wide range of materials, thicknesses, and complexities, making our cutting facilities adaptable to all your needs.

Comprehensive solutions for all your cutting needs.

At Active Steel Forge, our cutting services provide versatility, precision, and quality for a wide range of applications.

High-precision cutting for intricate designs with a clean edge finish.

Non-thermal cutting for materials sensitive to heat, ensuring accuracy and no material distortion.

Efficient cutting for thicker materials, offering speed without compromising quality.

Ideal for cutting thicker metals, ensuring clean cuts with minimal burrs.

Experience our state-of-the-art facility from anywhere

Founder/CMD

Team Size

Annual Capacity

Established

1

Understanding your specific requirements to tailor our cutting processes to your needs.

2

Choosing the right material and cutting method based on your design specifications.

3

Optimizing cutting parameters to ensure maximum precision and efficiency.

4

Rigorous testing and verification to ensure each cut meets industry standards and client expectations.

Stay ahead with our advanced cutting equipment.

At Active Steel Forge, we invest in the latest cutting technology to ensure superior results. Our facilities feature a variety of state-of-the-art machines designed for precision, speed, and versatility.

Tailored cutting solutions to meet every client’s unique needs.

At Active Steel Forge, we prioritize your specific project requirements and ensure the best cutting solutions for your needs. Our client-centric approach ensures that we deliver exactly what you need, on time and within budget.

Performance

Watch how we transform raw steel into precision-engineered components

Precision Rate

Components Cut

Client Satisfaction

Production Capacity

Their in-house capabilities and customization options have allowed us to streamline our production process. Highly recommended!

Maruti Suzuki

"The precision and durability of the components we receive from Active Steel Forge are unmatched. We trust them for all our forging requirements."

Ford Motor Company

Active Steel Forge has been a reliable partner for our manufacturing needs. Their commitment to quality and timely delivery has made a significant difference in our operations.

Hero MotoCorp Ltd:

Get in touch with our experts today