Raw Material Handling

At Active Steel Forge, we recognize that the foundation of…

At Active Steel Forge, we recognize that the foundation of…

At Active Steel Forge, we offer advanced heating facilities designed…

Experience unmatched cutting precision and efficiency with our advanced cutting…

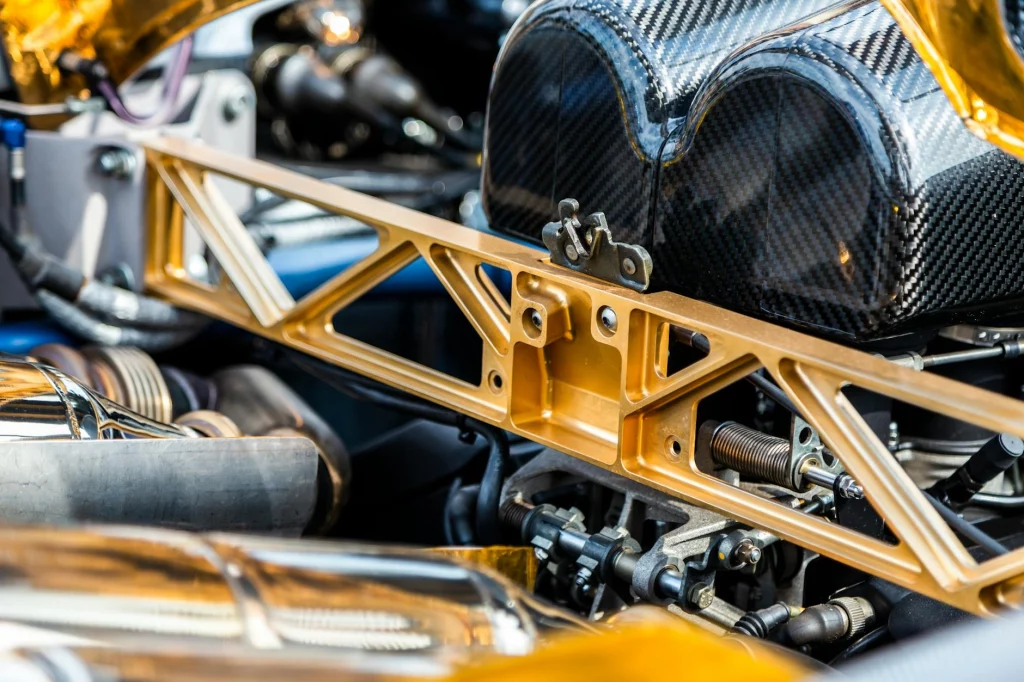

At Active Steel Forge, our advanced forging facilities offer unmatched…

At Active Steel Forge, we specialize in providing advanced heat…

Experience unmatched precision and superior quality with our advanced CNC…

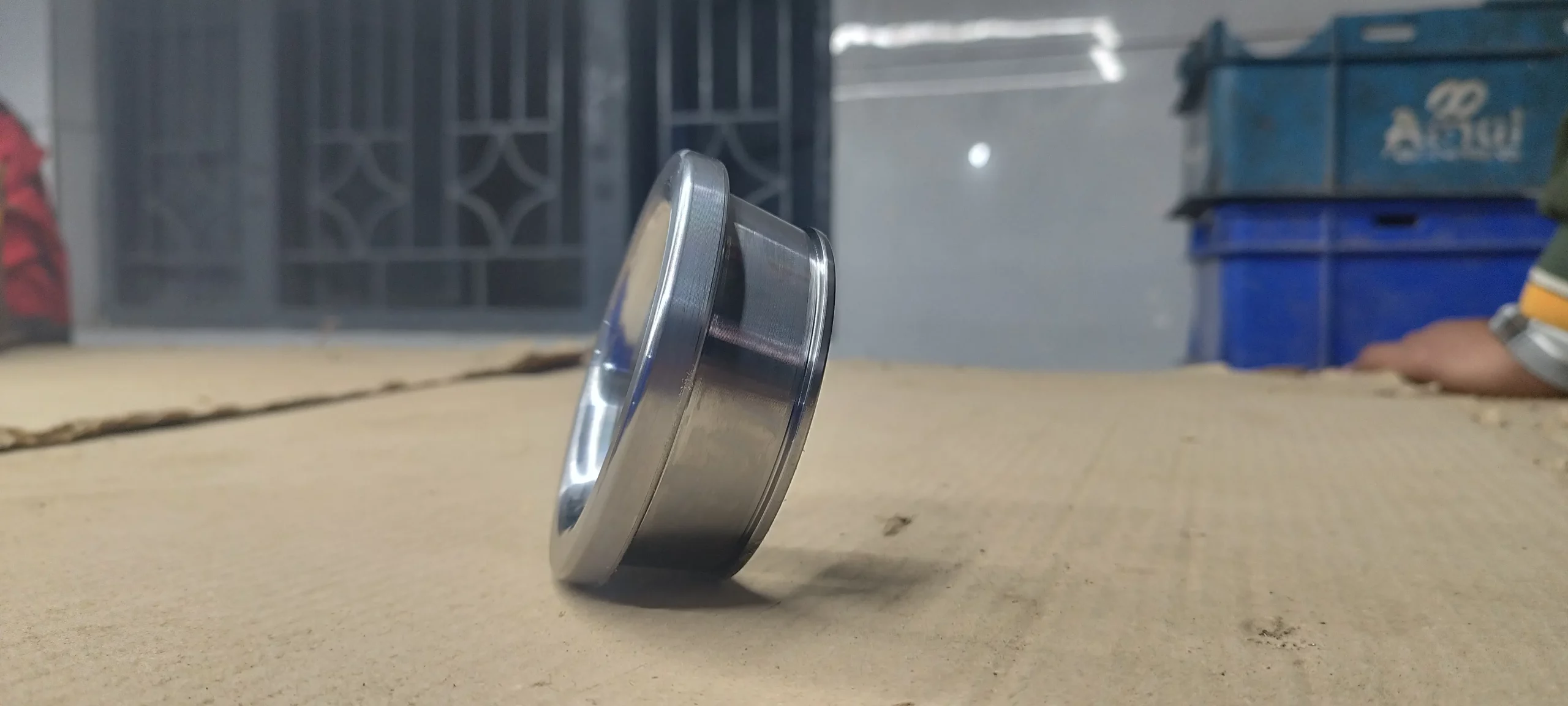

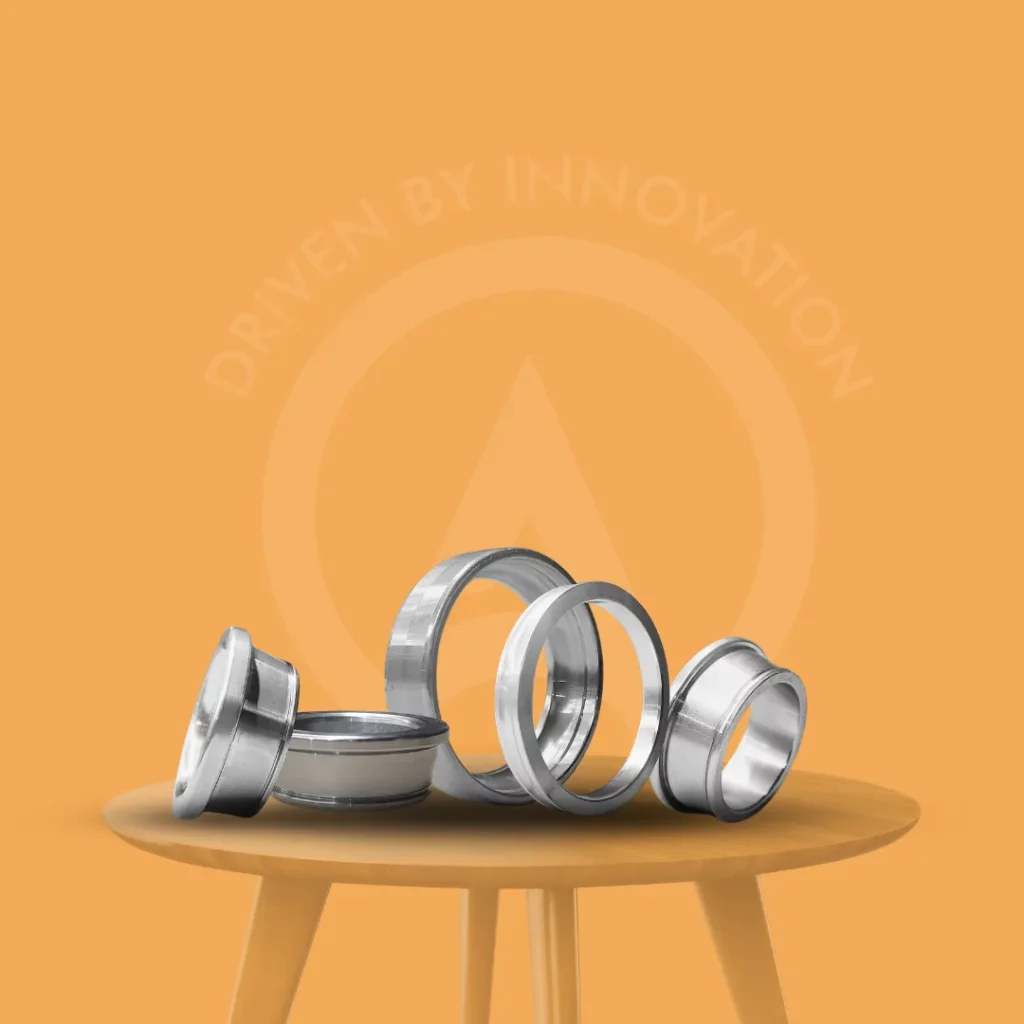

Engineered for durability and high performance in demanding applications.

High Durability

Built for long-lasting use.

Optimal Performance

Precision-crafted for superior results.

Material Excellence

Made with premium-grade steel.

Customizable Designs

Tailored to meet specific needs.

Explore our range of meticulously engineered bearing races.

Inner Diameter

45mm

Outer Diameter

85mm

Width

20mm

Load Capacity

Up to 15000 N

Max Speed

12000 RPM

Application Temperature Range

-40°C to 120°C

Grade

Premium Chrome Steel

Surface Treatment

Heat Treated

Hardness

58-62 HRC

1

Precision CNC cutting for raw material preparation.

2

Optimal heat treatment to enhance material properties.

3

High-pressure forging for structural integrity and strength.

4

Surface finishing and 100% quality inspection for reliability.

Each component undergoes thorough dimensional checks.

Regular hardness and material composition tests.

Stress and load capacity validation under real-world conditions.

Reliable for wheel hubs and transmissions.

Supports heavy-duty manufacturing equipment.

Perfect for turbines and power generation.

Wide-ranging uses across industries.

Experience our state-of-the-art facility from anywhere

We specialize in designing custom bearing races for your unique requirements.

Experience our state-of-the-art facility from anywhere

Get a glimpse of our advanced processes, from forging to quality inspection, through a virtual tour.

Their in-house capabilities and customization options have allowed us to streamline our production process. Highly recommended!

Maruti Suzuki

"The precision and durability of the components we receive from Active Steel Forge are unmatched. We trust them for all our forging requirements."

Ford Motor Company

Active Steel Forge has been a reliable partner for our manufacturing needs. Their commitment to quality and timely delivery has made a significant difference in our operations.

Hero MotoCorp Ltd:

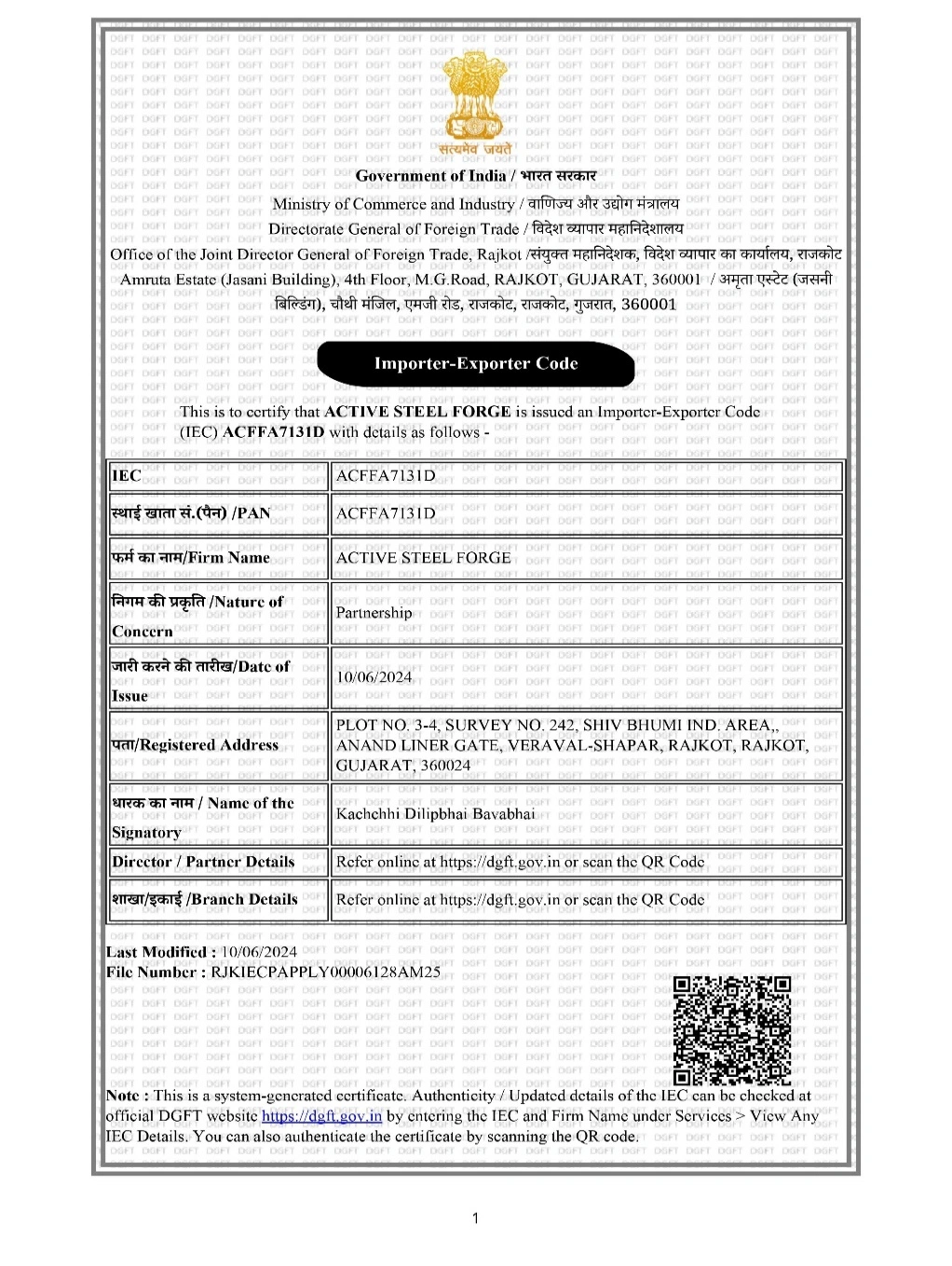

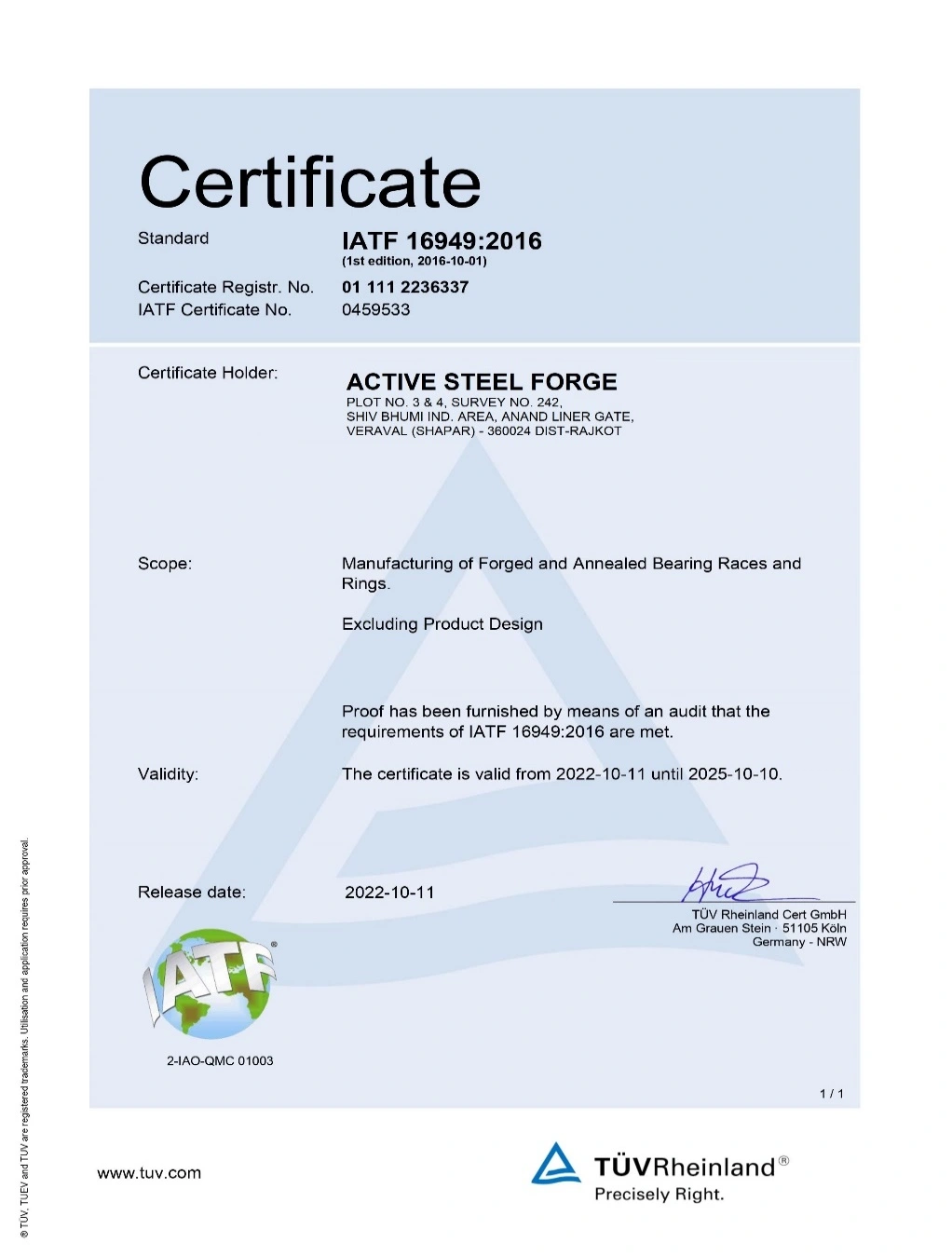

Active Steel Forge: Forged and machined components since 1999, with 4200 MT capacity and a skilled 180-member team.

+91 9909400022/21 / +91 9920952718

Plot No. 2, 3 , 4, Survey No. 242, Shiv Bhumi Ind. Area, Anand Liner Gate, Veraval (Shapar) – 360024, Dist. Rajkot (Gujarat) India.

Quick Links:

© 2025 Active Steel Forge All rights reserved.

Designed & Develop by Qrolic Technologies